Dust Suppression Nozzle achieves atomization through two primary steps:

Step 1: Fine water streams are sheared by high-speed airflow, forming initially atomized droplets.

Step 2: The primarily atomized droplets mix with high-speed airflow and impact the vibrating head, undergoing further atomization into ultrafine particles.

Function and Applications:

Exhibiting an exceptionally fine average particle size with minimal variation between the largest and smallest particles, the atomized water droplets demonstrate highly uniform granulometry. This promotes thorough integration between dust particles and mist droplets, significantly enhancing dust suppression efficiency.

Vibrations generated by the interaction between the vibrating head and high-speed airflow prevent dust and foreign matter accumulation in the nozzle orifice, ensuring consistent and reliable operation.

Typical Applications:

Dust control in mining and material handling operations

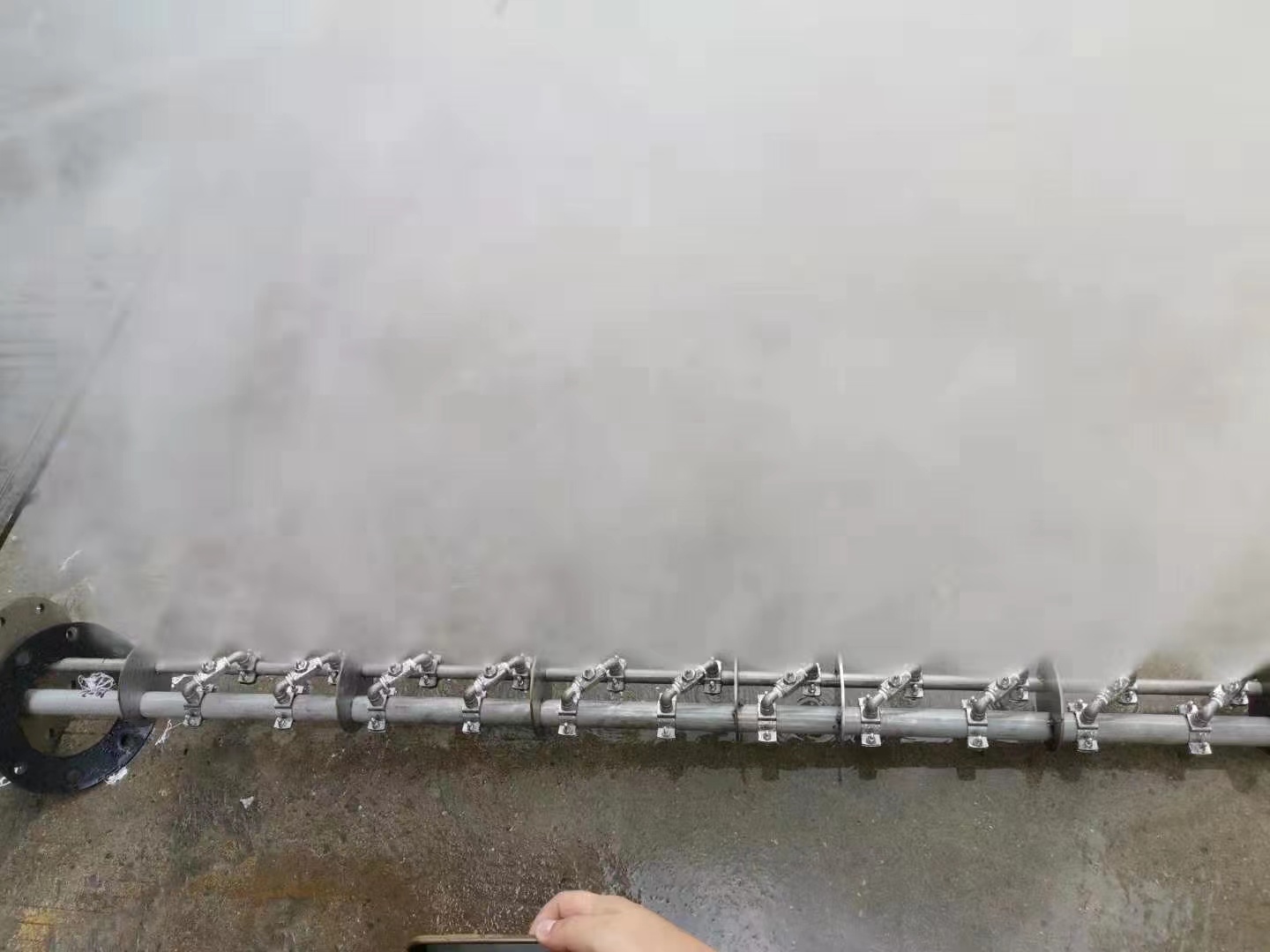

Industrial washing systems

Humidification processes

Mold release agent spraying

External Mixing Air Atomizing Nozzle,This ty...

The two-fluid atomizing nozzle comprises an a...

The two-fluid atomizing nozzle comprises an a...

The two-fluid atomizing nozzle comprises an a...